The evolution of cutting technology has been significant in shaping numerous industries, from construction to manufacturing. Key to this innovation has been the integration of diamond blades in various material processing applications. These blades, by virtue of their superior hardness and cutting efficiency, have allowed for precision and reliability that were unimaginable with their predecessors. This article explores how diamond blades have revolutionized the field of material processing by their design, efficiency, and longevity.

Introduction to Diamond Blades

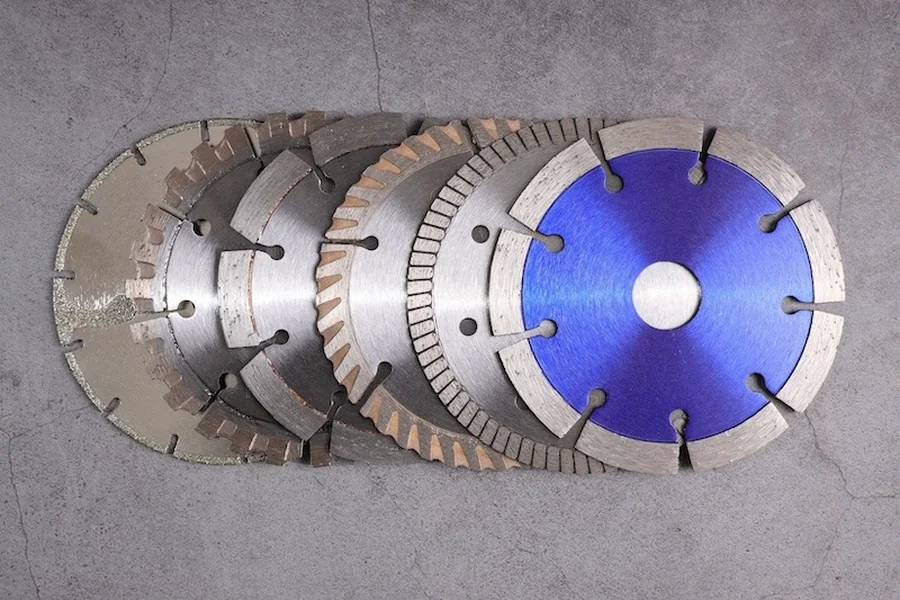

Diamond blades are saw blades that possess diamonds fixed on their edges, enabling them to cut through hard or abrasive materials such as concrete, stone, and asphalt. These blades operate by using the exposed diamonds to grind the material away, and as the diamond particles wear down, new, sharp diamonds are revealed, thus maintaining their cutting efficiency.

Innovation and Efficiency

The design of diamond blades is a testament to innovation in cutting technology. Unlike conventional cutting tools, which rely on toothed or abrasive edges, these blades are set apart by the embedding of diamond grit around their perimeter. This difference is not merely structural but functional, affording them a cutting capability that is both precise and swift.

The Durability of Diamond Blades

When it comes to longevity, diamond blades are unrivaled. Their robust construction makes them resistant to heat and wear, allowing them to maintain their cutting edge over prolonged use. This durability translates into economic efficiency, as fewer blade changes are necessary, reducing downtime and maintenance costs.

The Science Behind the Cutting

At their core, diamond blades are a study in advanced material science. Diamonds, being the hardest substance on earth, provide unmatched abrasion resistance. The metal core of the blade supports the diamonds, allowing them to maintain contact with the material being cut. The bonds that hold the diamonds affect the performance, with varying strengths suited for different materials and cutting conditions.

Impact on Various Industries

The contribution of diamond blades to industrial processes cannot be overstated. In construction, they facilitate the quick resizing of materials and demolition work. In the stone industry, they allow craftsmen to shape granite and marble with precision. Even the technology sector benefits, as these blades are crucial in cutting silicon wafers for electronics.

Advantages Over Conventional Cutting Methods

Diamond blades offer numerous advantages over conventional blades. They produce less dust, noise, and vibration, enhancing the working environment. Furthermore, the precision of cuts made by diamond blades means that less material is wasted, enhancing efficiency and promoting sustainable practices.

The Environmental Angle

One seldom-discussed benefit of diamond blade technology is its environmental impact. The precision and efficiency of these blades can lead to a significant reduction in waste materials. This not only leads to cost savings but also reduces the environmental footprint of construction and manufacturing activities.

Safety Improvements

Improved safety is another aspect where diamond blades stand out. The lower levels of vibration and noise reduce the risk of hearing damage and hand-arm vibration syndrome among workers. The clean cuts also minimize the risk of accidents related to material breakage.

Customization and Versatility

Diamond blades are highly customizable, affording them a versatility that can be tailored to specific cutting tasks. Whether for wet or dry cutting, simple or complex materials, there is a blade design that matches the job requirement, ensuring optimal performance.

Technology Evolution and Future Prospects

The technology behind diamond blades continues to evolve. Modern manufacturing techniques are continually refining the production of these blades, enhancing their cutting properties and expanding their range of applications. The future promises even greater achievements with the potential integration of new materials and designs.

Financial Implications

The initial purchase price of diamond blades may be higher than traditional blades, but their cost-effectiveness over the long term is clear. The extended lifespan and reduced need for blade replacement result in a lower total cost of ownership, a critical consideration for businesses seeking to optimize their operations.

Conclusion

Diamond blades are undeniably at the cutting edge of material processing technology. Their remarkable durability, efficiency, and precision provide significant advantages over conventional cutting methods. Industries that have adopted this technology testify to its impacts on quality, safety, and cost savings. As we look to the future, the continued innovation in diamond blade technology holds the promise of further advancements in industrial processing, contributing to a more efficient, economical, and environmentally conscionable approach to material cutting.

Embracing the Cutting Edge

For professionals and industries ready to embrace the cutting edge in material processing, selecting high-quality diamond blades is essential. By choosing blades that match their specific needs and applications, users can ensure they reap the maximum benefits in terms of efficiency, precision, and operational cost savings.

In conclusion, diamond blades have not merely changed the game; they have created a new standard for performance in material processing. Their revolutionary impact continues to shape the landscape of industries requiring precise, efficient, and long-lasting cutting solutions.